Teka TPZ Planetary mixer achieves environmental and financial savings for major roof tile producer

Teka TPZ replaces rotating pan mixer, saving 68,000kWh of power per year.

£40,800

Annual-Saving

23.8t

Annual CO2 Saving

43%

Return-on-investment

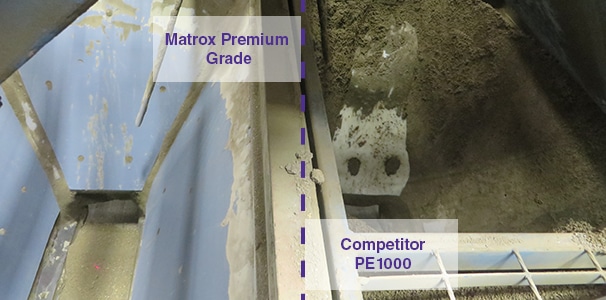

“The performance difference between our standard polyethylene & Matrox is astounding. Matrox keeps this tricky material moving and a significant maintenance hotspot has been eradicated. The photograph really does speak for itself, not all polyethylenes are created equally!” – Fitter

A leading Roof Tile manufacturer was experiencing severe build-up in a number of PE1000 lined holding hoppers. The dry concrete mix was sticking to the hopper walls disrupting production. Operatives regularly agitated the encrusted material using a rod, this action caused damage – allowing product to build-up and set behind the liners. Eventually, the set concrete would then fall into the screw-feed & damage the flight.

Matrox Premium grade UHMW polyethylene

Competitor PE 1000 – constant build-up, cleaned every 15 minutes. Screw flight regularly damaged & replaced

Matrox Premium – no build-up, no cleaning, no damage

Key Features

Benefits

Efficiency – consistent flow of material from hopper to screw-feed

Productivity – production line availability increased

Maintenance – vastly reduced

Safety – hoppers accessed via ladder, visits reduced