Mixers

TEKA pan, planetary, turbine & twinshaft mixers. High efficiency, low maintenance mixing.

We believe that mixing is at the heart of the concrete production process. Achieving an homogeneous mix is critical for a high quality end product, yet this can often be difficult to achieve consistently in practice due to a wide range of factors. We have over 40 years experience in this area and we’re renowned for our expertise in improving the mixing process and breakdown support, be it through spare parts or new mixing equipment.

TEKA pan, planetary, turbine & twinshaft mixers. High efficiency, low maintenance mixing.

Remove concrete build-up in mixers before it hardens with Walter Cleaning Systems

Improve working conditions and aid regulatory compliance whilst reducing product waste

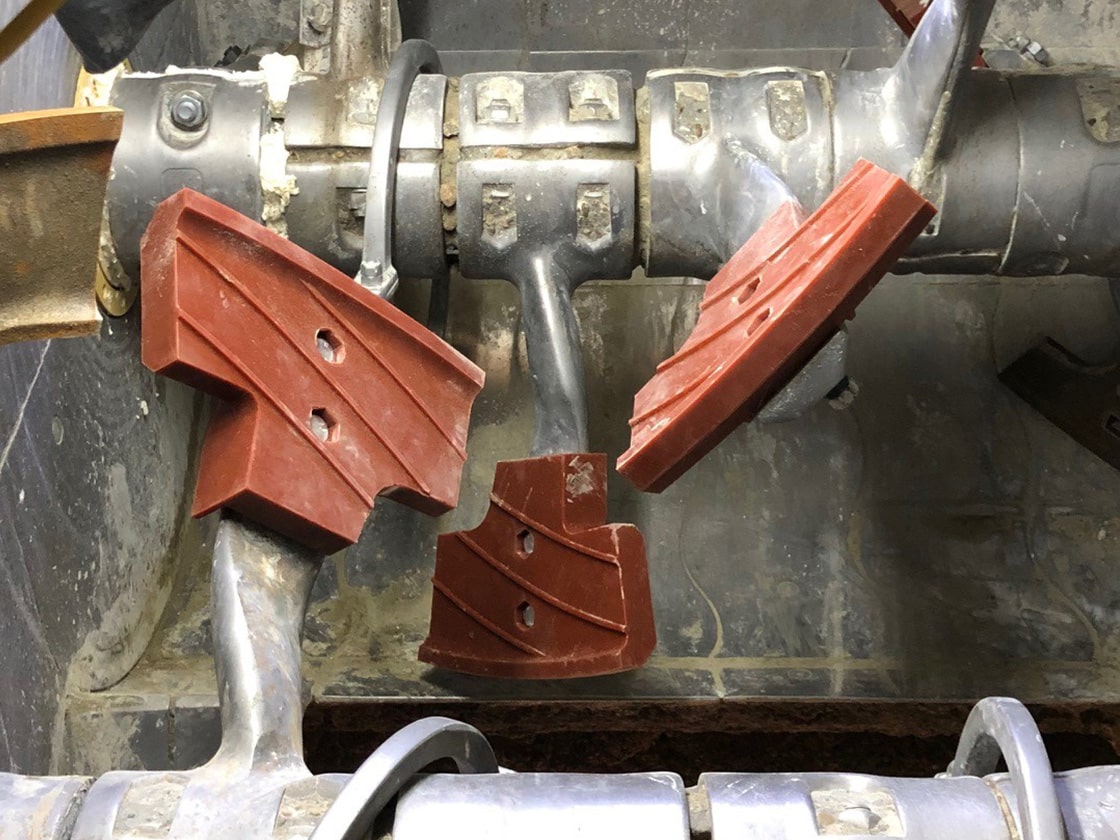

Enhance mixing performance and reduce maintenance costs with our wide range of components

Reduce maintenance and cleaning in a difficult-to-access area