Taking A Look At Centrum Pile Ltd's New TEKA THZ

It was great to visit Centrum Pile Ltd recently to see their newly commissioned TEKA pan mixer. The new TEKA THZ3000A (2m³) machine replaces an ageing 1.5m³ pan mixer.

Read ArticleDust is a common problem on concrete plants and construction sites across the UK. It is both a nuisance and a potentially deadly hazard.

It’s something which site operators need to pay close attention to when it comes to managing health & safety.

At the Precast 2018 conference and expo, which ConSpare attended, John Rowe, The Health and Safety Executive’s (HSE) Head of Manufacturing, talked about the growing problem of exposure to substances which cause occupational lung disease in manufacturing and construction environments.

This has become so much of a concern to the HSE that it has been identified as a key priority in its latest strategy to improve workplace health across the sector.

Evidence shows that respiratory exposures have, traditionally, been a particular problem in the construction sector.

Workers in the construction sector are one of the most at-risk groups because of the dust that they breathe.

The incidence of serious illnesses and deaths caused by respiratory health hazards in the sector is predicted to continue if the issue is left unaddressed.

That’s why the HSE is calling for a ‘cultural shift’ within the sector, to include more effective management of the risks, to help reduce the burden of lung disease within the construction sector.

It’s clear that dust escaping to atmosphere around any plant is a major health risk. Limiting the level of dust site staff are exposed to is a priority throughout the industry. For example, dust emission from concrete mixers during the batching cycle can present a significant problem.

For these types of process issues, ConSpare can help provide the solution.

‘Make it better’ can help plant operators identify and address key issues across their plant to improve site safety for workers and visitors. We’ve taken more than 40 years’ experience of the entire end-to-end concrete production process and used it as the base to develop our ‘Make it better’ approach.

It enables us to assess the whole concrete production process and utilise specialist products to provide solutions which improve specific plant operations.

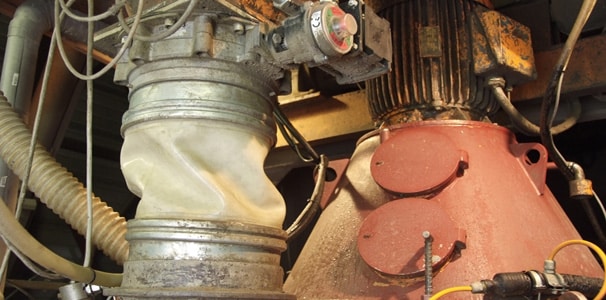

As a leading supplier of filter units and filter replacement parts for the concrete industry, we have sourced and identified innovative, industry-leading products – such as the CDX ConicalAir MixerVent designed to reduce dust emission on the mixer platform.

Our efficient and effective filtration system helps improve working conditions and aid regulatory compliance while reducing product waste.

Selecting dust tight flexible connectors to join machinery and pipework, such as the BFM fitting connector system and ClearFlex also helps limit material leakage as it flows through the plant.

Conveyors can also be a significant source of dust, whether at conveyor transfer points during loading or via dirty and dusty belts carrying material around the plant. Our conveyor components can contribute significantly to the removal of unwanted “carryback” material from the belts and provide an effective seal at transfer points.

To find out how our expert team can help you ‘Make it better’ when it comes to site safety, get in touch today.

It was great to visit Centrum Pile Ltd recently to see their newly commissioned TEKA pan mixer. The new TEKA THZ3000A (2m³) machine replaces an ageing 1.5m³ pan mixer.

Read Article

ConSpare will showcase a wide range of problem-solving products at key events and exhibitions for the UK concrete industry in 2026.

Read Article