Taking A Look At Centrum Pile Ltd's New TEKA THZ

It was great to visit Centrum Pile Ltd recently to see their newly commissioned TEKA pan mixer. The new TEKA THZ3000A (2m³) machine replaces an ageing 1.5m³ pan mixer.

Read ArticleMoisture in sand and aggregates is the hidden variable in the concrete production process, and failure to accurately identify this water content in each batch has a significant effect on product quality and the cost of production.

Hydronix microwave moisture equipment has successfully helped concrete producers accurately measure moisture in both the raw materials and finished product since 1982. Hydronix sensors, interfaces, and software help clients to batch the correct weight of sand & aggregates regardless of water content, resulting in:

• Highly accurate control of the aggregate / cement ratio in each batch

• Reduced cement wastage. Improved Standard Deviations

• Improved yield and productivity

• Fewer reject batches

• A significant reduction in the carbon footprint of production

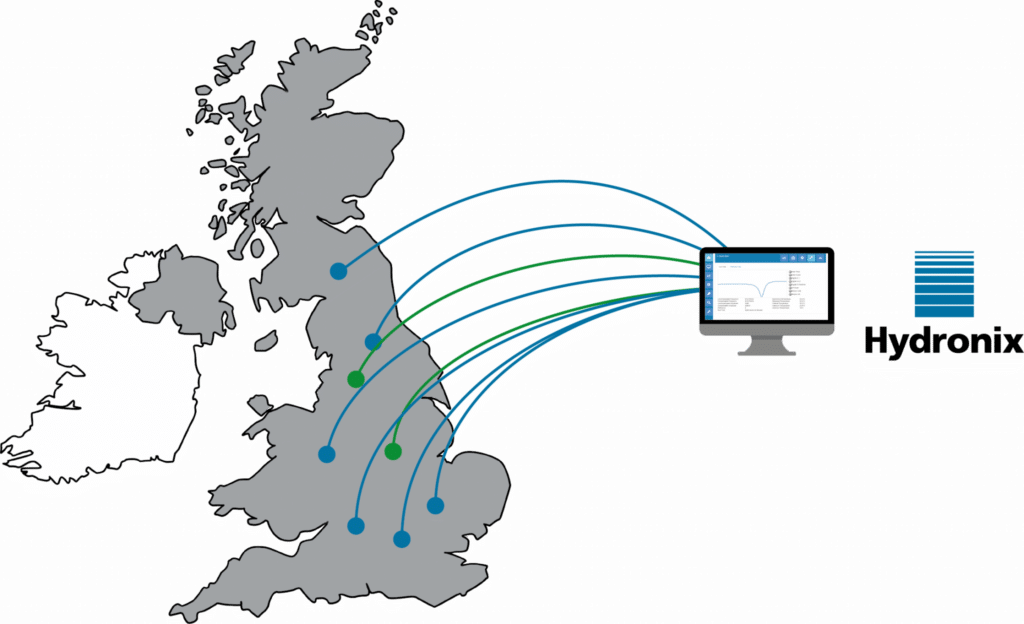

Having pioneered the use of microwave energy to measure moisture, and with over 95,000 sensors installed worldwide, Hydronix are in a perfect position to continue innovating in this specialist field. A major area of development recently has improved remote access and monitoring of moisture data – via web browsers, industry standard interfaces and APIs.

(Hydro-Probe installation in a sand bin)

Traditionally, data from the Hydro-Probe sensors located in aggregate bins, hoppers, or on conveyors, was only available locally “on-site”. All activities surrounding moisture measurement had to be undertaken and monitored from a static location on the plant, one plant at-a-time. For concrete producers with large plants or with sites at multiple locations, this could make the process of calibrating, configuring, and monitoring sensors and their outputs onerous. A standardised approach to moisture measurement across multiple sites and access to key moisture data centrally was also difficult to achieve.

With modern network connected systems, online moisture sensor data can be viewed “live” and sensors can be accessed from any location. The latest innovations allow for remote access, monitoring, and servicing of probes and data across a number of different concrete plants and locations – all of which can be viewed via a web enabled PC, tablet, or phone. These developments put valuable moisture measurement information in the hands of centralised technical teams for increased visibility and efficiency.

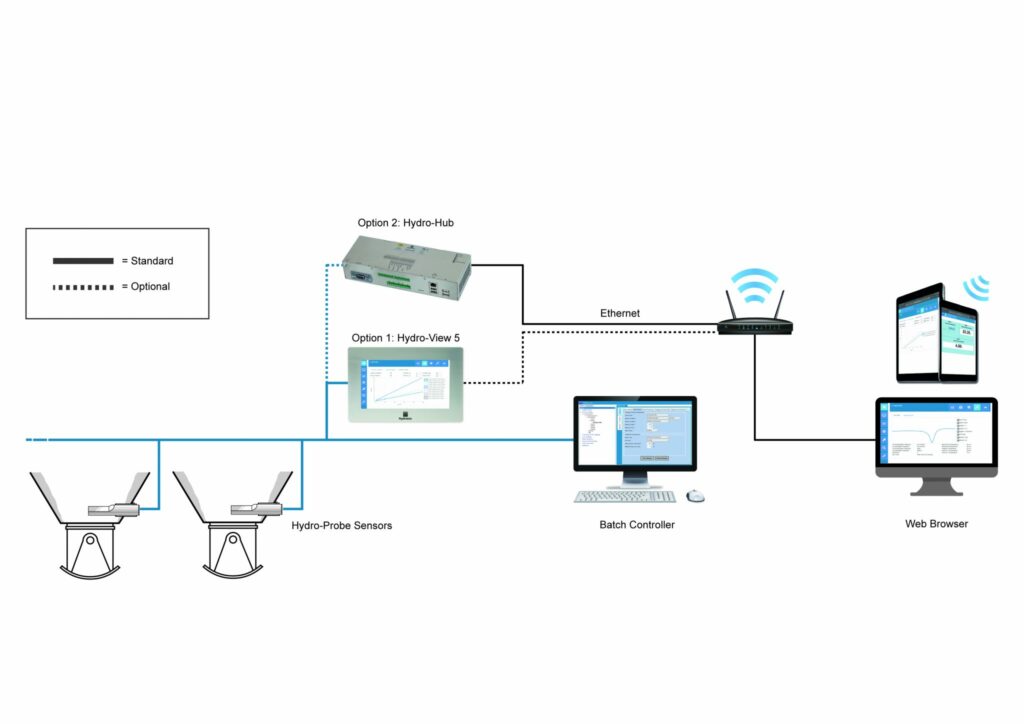

When measuring moisture in aggregates, Hydronix has two interfaces which enable Hydro-Probe sensors to be accessed via standard web browsers – the Hydro-View and Hydro-Hub.

The Hydro-View 5 unit is the standard option in our range. It has a versatile 10.1” colour touchscreen to enable a local onsite operator interface with Hydronix sensor networks whilst retaining the standard connectivity with the batching control system. When connected to a local area network, this functionality is also available via a standard web browser running on any PC, tablet, or similar device.

The Hydro-Hub gives the same functionality without the local display, providing a cost-effective solution for remote only operations.

Both units allow users to view Hydronix sensor data in addition to sensor configuration, diagnostics, calibration, and data collection. They can connect to a network of up to 16 Hydronix sensors with multiple systems simultaneously. Connections can be made using TCP/IP, existing RS485 networks implementing the Hydro-Link Protocol or through the Fieldbus option.

Hydronix delivers web functionality through Hydro-Net software which is built into the Hydro-View and Hydro-Hub interfaces. Features of Hydronix’s Hydro-Net software include:

• Web browser access to all screens

• Live display to view measurements of up to 6 sensors

• Calibrate Hydronix sensors remotely

• Log sensor data

• Sensor Configuration

• Diagnostics

• API access to sensor values

• Part of the Hydronix digital eco-system giving access to sensor networks from remote Hydro-Com clients for calibration, diagnostics, and monitoring

If you’d like to find out more about using Hydronix’s web enabled moisture measurement equipment, then please contact our Capital Projects team. They can advise on the best configuration for your plant and requirements.

In addition to measuring moisture in aggregates, Hydronix is also the leading technology for controlling moisture in the concrete mixer. The system can automatically calculate how much water is required for each batch and identifies when the mix reaches homogeneity. This ensures raw material wastage is minimised, reject batches are reduced, and mixing time is optimised.

It was great to visit Centrum Pile Ltd recently to see their newly commissioned TEKA pan mixer. The new TEKA THZ3000A (2m³) machine replaces an ageing 1.5m³ pan mixer.

Read Article

ConSpare will showcase a wide range of problem-solving products at key events and exhibitions for the UK concrete industry in 2026.

Read Article