LATEST GENERATION WATER CONTROL SYSTEM RELEASED

Hydronix digital microwave moisture measurement equipment improves the efficiency of concrete production. Accurate and reliable moisture measurement in both the raw materials and finished product helps concrete producers reduce costs, wasted materials and CO2 associated with production.

Hydronix pioneered the microwave technique and has gone on to become market leader. The equipment is tried and tested with over 85,000 sensors installed worldwide, and they continue to develop solutions and new products using the latest technology. The latest of which is the next generation water control system, Hydro-Control 7.

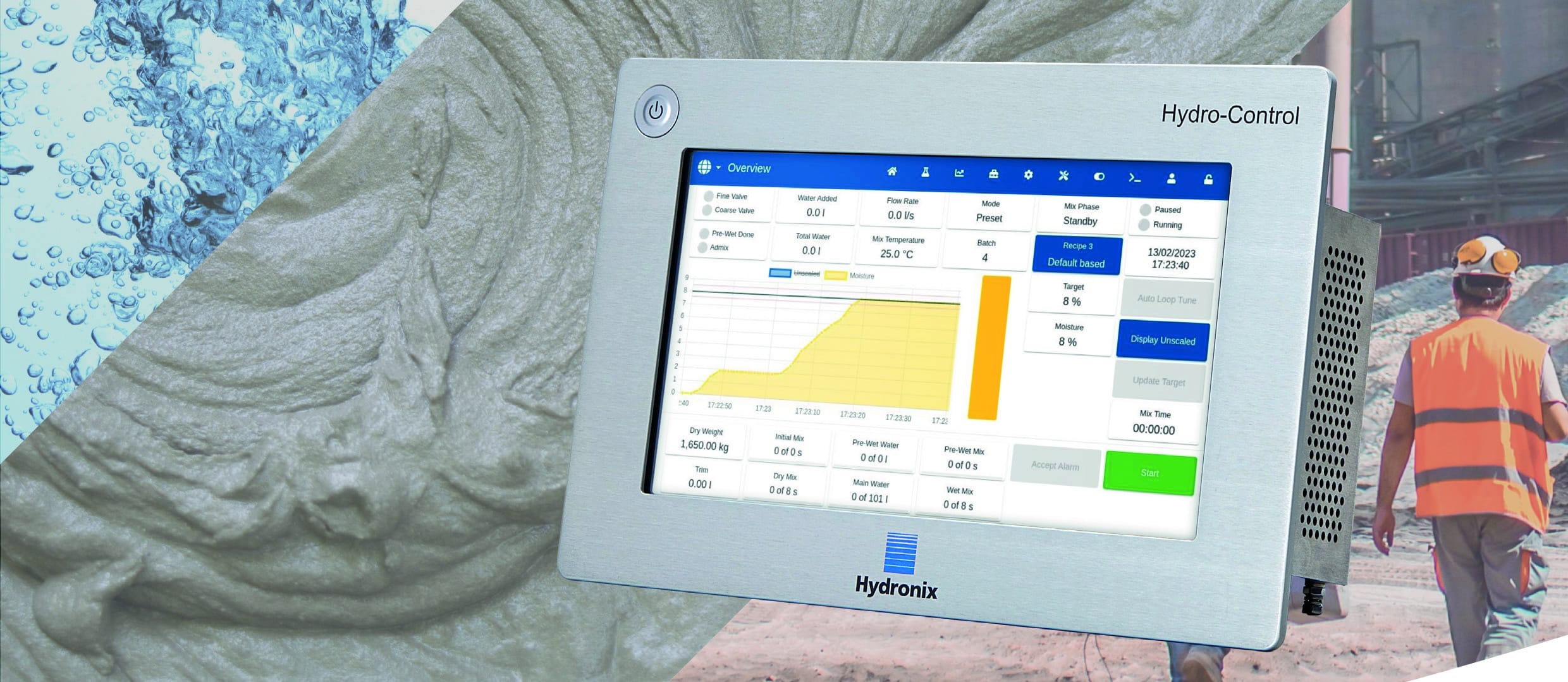

New Hydro-Control (HC07) – The intuitive touch screen water control system

The Hydro-Control (model HC07) is the latest generation of Hydronix’s renowned water control system. It provides an easy method for controlling the mix cycle to ensure that the correct amount of water is automatically added in the shortest possible mixing time.

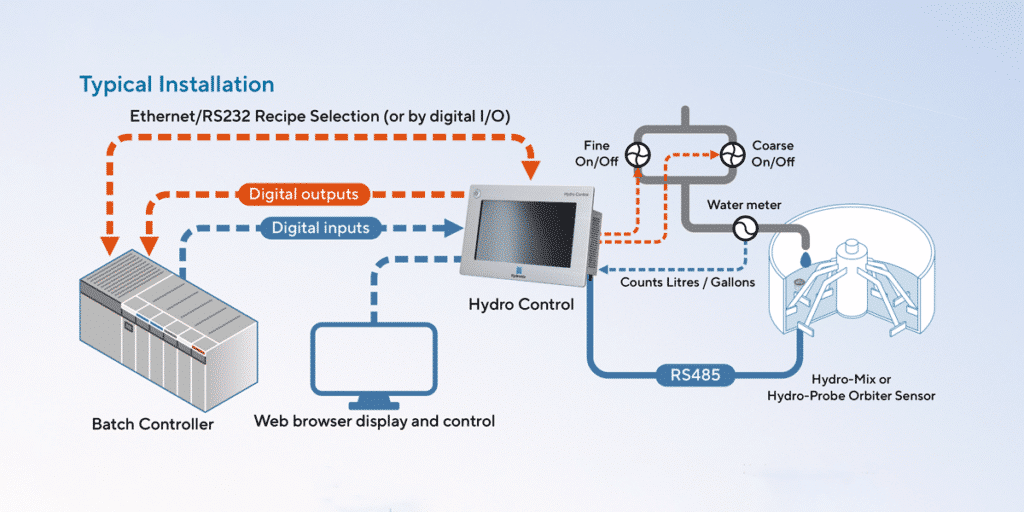

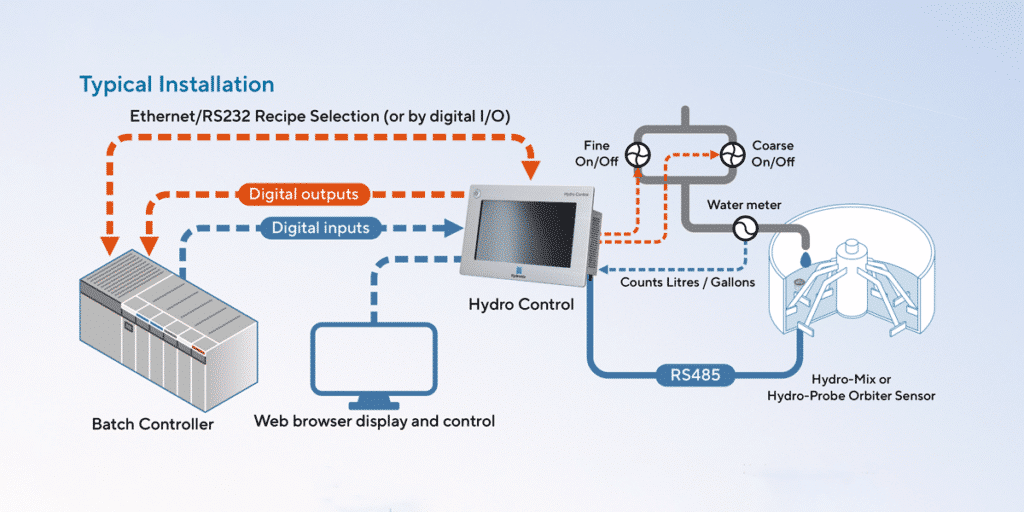

Using the reading from a Hydro-Mix or Hydro-Probe Orbiter sensor installed inside a mixer, the unit accurately and continuously monitors, displays and adjusts the moisture levels of the material throughout the mix cycle. Using known recipes, the Hydro-Control (HC07) automatically calculates and adds the correct amount of water to the mix. This ensures that the required moisture target can be easily achieved, batch after batch.

With features such as automatic recipe selection and a 10.1” colour touchscreen display, the unit is designed for simplicity of use and integration into new or existing control systems.

Highly versatile and offering comprehensive connectivity

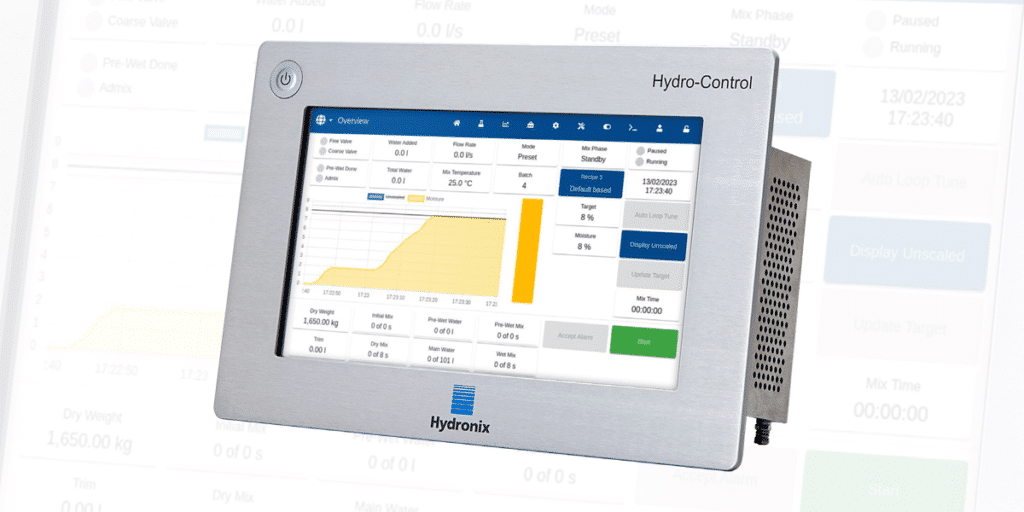

The highly versatile unit accurately adds water into a mixer via weighed, metered, and timed methods. Over 99,000 recipes can be stored on the unit and different operating modes can be chosen for each recipe, enabling the most suitable option to be selected.

The latest release of the Hydro-Control enables connection to a control system via ethernet, WEB API or an RS232 serial link. It is now possible to secure remote access through a web browser.

Neal Cass, Sales Manager at Hydronix, explains that “at Hydronix, we understand our customers’ challenges and data connectivity is becoming vital. We have updated the Hydro-Control with connectivity in mind, and the updated unit provides a flexible connection to control systems and PC.

The Hydro-Control uses a Linux OS and has had a major overhaul of its user interface whilst remaining familiar to existing Hydro-Control VI users. It’s more intuitive and easier to use. It was important to us that our customers have a better experience with the unit and that the look and feel are like our other products.”

The benefits of controlling moisture in the mixer

Accurately measuring moisture in the mixer optimises the entire mixing and production process. The system automatically calculates exactly how much water is required for each batch and identifies when the mix reaches homogeneity, ensuring repeatability batch after batch. Providing the following benefits:

• Minimise waste & reject batches, reducing CO2

• Consistent concrete workability

• Automatically control cement / water ratio

• Maximise concrete product quality

• Excellent Return On Investment

For a quick introduction – Click here to download our Batching Process Improver Guide.

Discover more

Contact our Capital Projects Team to find out more about Hydronix and the new Hydro-Control. Call 01773 860796, email sales@conspare.com, or complete our contact form.

Pictured: Nick, Alex and Chris from the Capital Projects Team