Hydronix digital microwave moisture measurement equipment improves the efficiency of concrete production. Accurate and reliable moisture measurement in both the raw materials and finished product helps concrete producers reduce costs, wasted materials and CO2 associated with production.

Established in 1982, Hydronix pioneered the microwave technique and has gone on to become market leader. The equipment is tried and tested with over 85,000 sensors installed worldwide, and they continue to develop solutions and new products using the latest technology.

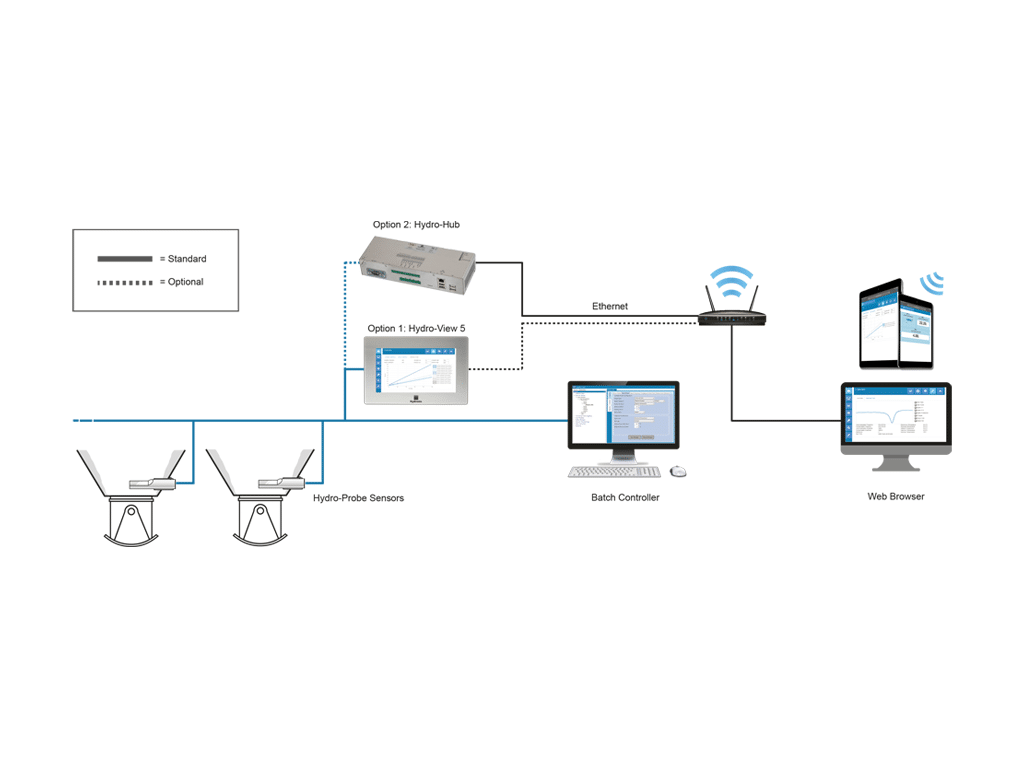

Moisture in sand and aggregates is the hidden variable in the process. Failure to identify this water content has a significant effect on the cost of production, the carbon footprint of the plant, and product quality. Hydronix measures moisture in each batch, transforming mix design accuracy and reliability.

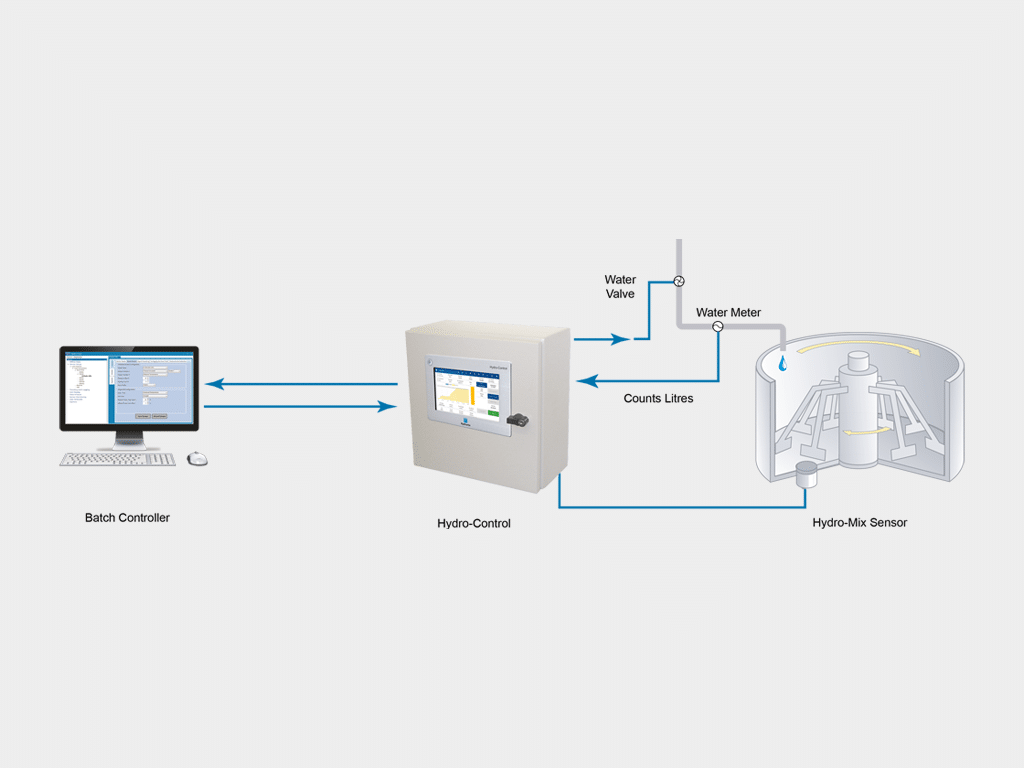

Accurately measuring moisture in the mixer optimises the entire mixing and production process. The system automatically calculates exactly how much water is required for each batch and identifies when the mix reaches homogeneity, ensuring repeatability batch after batch.