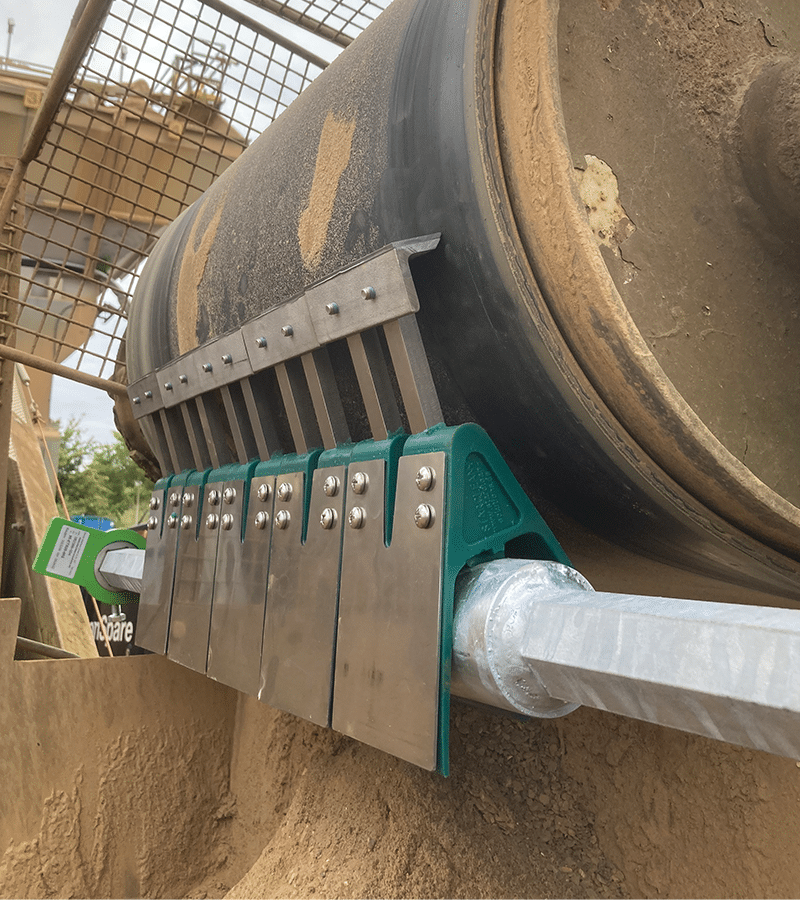

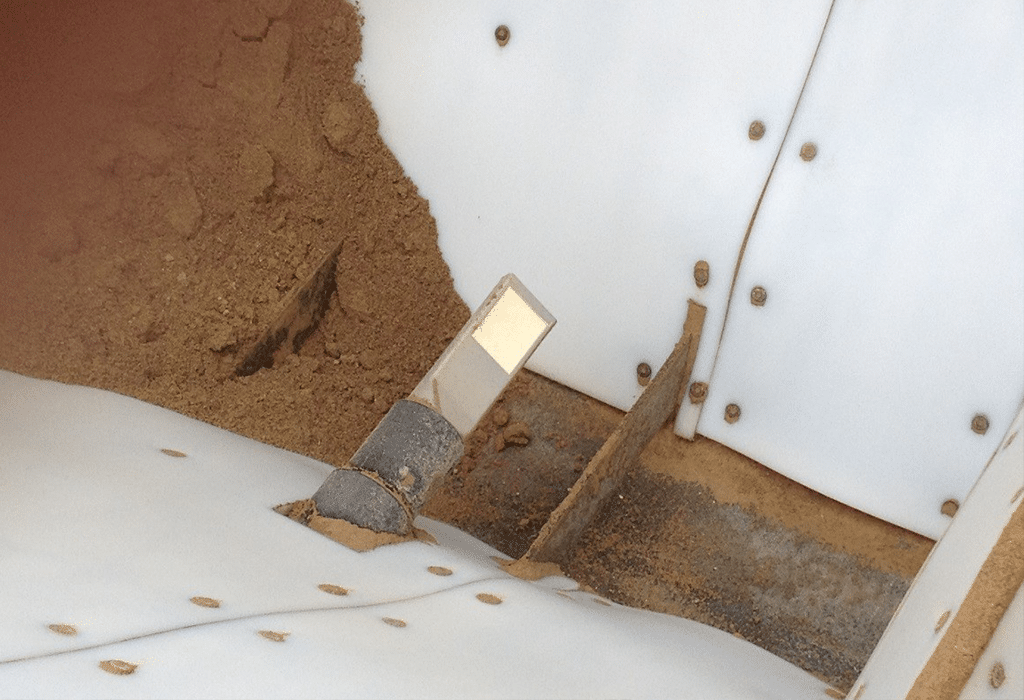

HS2 Plant Manager thrilled with STARCLEAN® belt cleaner performance

Plant manager replaces OEM scrapers with STARCLEAN® belt cleaners, cutting carryback, reducing maintenance and offering superb service life

90% reduction

in maintenance requirements

+180 wheelbarrows

of carryback saved in a year

2% blade wear

within first 12 months of operation