Starclean scrapers are manufactured by F.E Schulte Strathaus GmbH & Co. KG, one of Europe’s largest and most respected belt cleaner manufacturers. The Starclean range incorporates the ingenious twist-swing tensioning mechanism which ensures blade contact to the belt regardless of individual segment wear for excellent cleaning performance, minimal maintenance and cost effective operation.

This unique, site proven design is different to traditional scrapers and offers far better reliability. A key design feature is within the unique tensioning devices. The simplicity of the quick-release mechanism and quick-change, slot-in blade design means in-house site staff can quickly and safely carry out tool-less maintenance. It literally takes seconds to disengage, maintain and re-tension, keeping maintenance costs and downtime to a minimum.

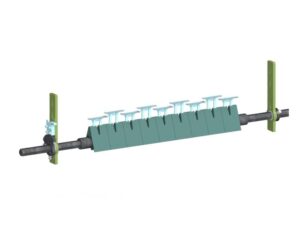

A primary position pre-cleaner which is highly effective at removing carryback from the conveyor belt, particularly in applications conveying high tonnages, wet and coarse material. Typically fitted at the ‘on head’ position of the head pulley, the system utilises specially formulated, belt friendly, polyurethane blades that adapt to the belt surface – even after wear.

A primary position cleaner which is extremely effective at removing fines and moisture from the belt. This cleaner is typically fitted at the ‘on head’ position of the head pulley and provides an alternative to ‘under belt’ secondary cleaners where space limitations impede installation. Abrasion resistant tungsten carbide blades ensure maximum cleaning performance and minimal adjustment.

The Starclean secondary scraper provides the benchmark for high efficiency removal of fines and moisture, offering the highest levels of conveyor cleaning performance. This cleaner is typically fitted in the ‘under belt’ position on or behind the nip point. Abrasion resistant tungsten carbide blades ensure maximum cleaning performance and minimal adjustment.