The THT is a mixing revolution. The unique MixTurbine design is optimised for use with the highest standard premium concretes and the most difficult mixing tasks. The sweep of the MixTurbine generates a swing and throw effect, resulting in high intensity mixing with very little energy wasted ‘outside’ of the mixing process. THT is highly flexible, perfect for variable batch sizes and regular changes of product.

The robust and compact drive system can be fitted with a frequency converter. This ensures the optimal rotation speed of the MixTurbine which is adjusted for the specific batch and provides an ideal mixing effect. This also allows varying mixing intensities during the different stages of a single mixing cycle.

THT is ideally suited to the demands of; face-mix, fibre, foam, self-compacting, colour and ultra-high strength concretes.

THT mixers are custom built to user specification with variable elements including the gearbox and motor drive system, mixing pan diameter, and number of MixTurbine mixing tools. Sizes range from 250 litres to 3000 litres (0.17m³ to 2m³ concrete output). Machines can be specified with up to 4 discharge doors, skip hoists, and a wide range of mixer wear plates and wear parts.

To get the most from your investment in a new mixer, you can also specify:

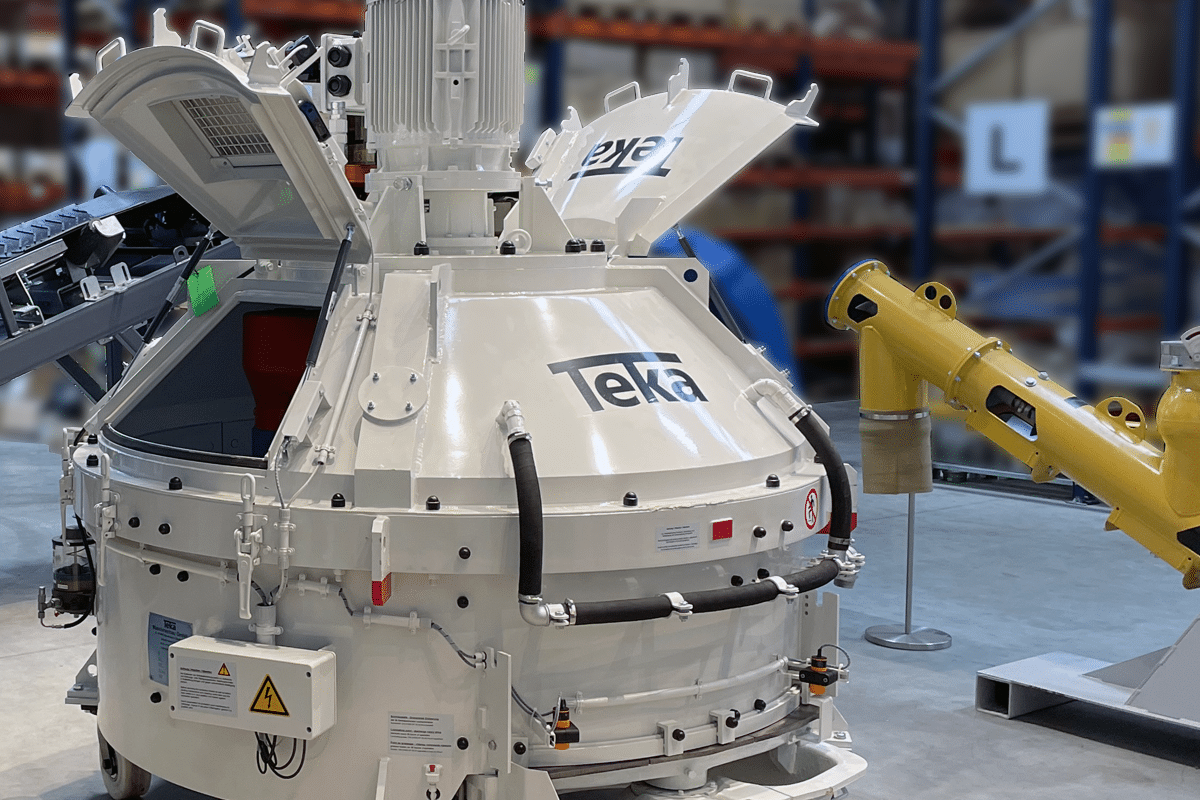

At our Castlewood premises we have a large selection of equipment available to view within our demo area. A key piece within the room is our Teka THT type E-1-3 mixer.

The machine is a 750 litre (0.5m³ concrete output) version, with 30kW electric motor and 3kW hydraulic drive. It features a single MixTurbine and tungsten-carbide coated discharge scraper. The mixer is currently configured in “show spec”, showcasing multiple wear plate options, a Walter RD3 mixer washout cleaning head, and a Hydronix Hydro-Mix probe.

The biggest benefit of this particular THT machine though is that it is available to purchase ex-stock, allowing clients to invest in the latest mixing technology with minimal turnaround.

If you’d like to arrange a visit to inspect the THT, or to request a full specification for the machine, please get in touch with the Capital Department.

The patent pending MixTurbine mixing tool combines two sweeping arms which generate a new ‘swing and throw effect’. The shape of the turbine mixing tool causes raw material to naturally accelerate across the face of the mixing arm as it rotates, powerfully sweeping the mix from one side of the pan to the other. Every full cycle of the MixTurbine around the pan causes maximum movement. This constant ‘throwing’ action has proven to produce a highly intensive mixing effect.

All mixing is done at ground level. Mix on the pan floor is swept across the pan, creating an empty space behind the MixTurbine arm, which is immediately filled as the upper layer of mix falls into the space left behind, using gravity to achieve the much sought after dual layer mixing effect. This plays a key role in minimising balling.